GBP

/

GBP

/

Shipping to:

Currency:

Polishing (Cut) Process

The polishing process consists of six considered steps to ensure that the perfect outcome is achieved.

Marking the stone – The first step involves marking the stone. The rough diamond will be fully assessed to determine the best way to cut it so that maximum value is extracted. This will involve looking at the inclusions and where they are situated.

Cleaving (optional step) – Not all diamonds go to the cleaver, however the majority of large stones do. This is a vital part of the process because the diamond could end up shattered if the cleaver or the planner made any errors. So, how does cleaving work? Firstly, a groove will be cut along the line using a different cutting tool. This prepares the area, showing where the stone is going to be cleaved. After this, the cleaver is mounted and a steel wedge is inserted into the groove. The cleaver then uses a mallet to strike the wedge so the diamond splits along the line.

Sawing– There are specialist saws for diamond cutting, which can rotate at around 4,000 revolutions per minute. Consequently, it can take up to eight hours to saw through a one-carat diamond. However, the process can take even longer if a knot gets in the way. One thing we are noticing is that an increasing number of companies are investing in laser equipment to cut their diamonds, and this is because they are more efficient and precise. In fact, the accuracy is remarkable, as there is no cutting edge to wear down.

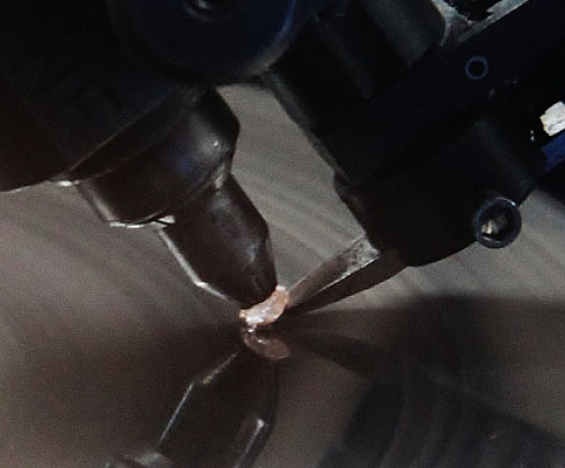

Rounding –Rounding, which is also known as bruiting and girdling, is the fourth part of the process. This is designed to ensure the diamond is rounded into a cone shape. It involves placing the stone in a chuck of a lathe. A second diamond is mounted on the end of a long handle and held against the diamond while it spins.

Faceting – There are two parts to faceting. Firstly, the 18 main facets will be placed by a lapper. After this, the remaining 40 facets are created and polished by the brillianteer. Of course, this applies to when a Round Brilliant diamond is being created.

Finishing touches– Finally, the diamond will be inspected carefully. If approved, dust and oil will be removed by boiling the diamond in sulphuric acids and hydrochloric acids.